Quality with passion.

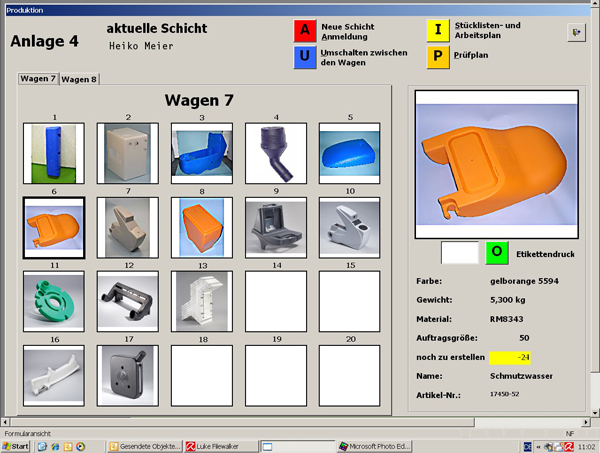

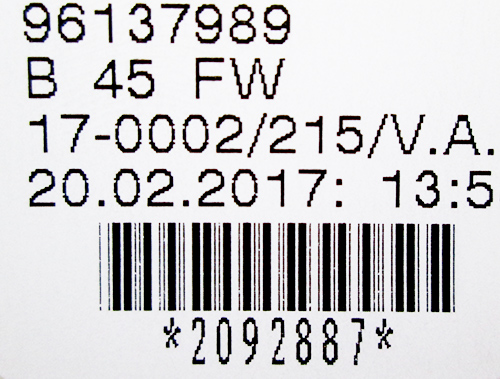

To guarantee the quality you need for your high-quality and demanding products we have developed an own software. This makes it possible to track every part with the help of a barcode Instead of only to spot check we record every step of the production.

This allows us to reproduce the production process with a production journal and we are able to guarantee process-safety and reproducibility. The satisfaction of our customers is very important for us. Therefore nothing is left to coincidence.

guarantee the precision needed for your products we only use modern machinery with highly precise controls. To ensure that our staff is always doing the right things they are trained regularly. In addition, every machine is equipped with a terminal that enables every staff member to control him or herself. Our software contains detailed part lists with information such as storage location, mould and amendment index.

Complex production schedules lead our production specialists through each production stage. Based on control plans the hollow-bodies are finally controlled, labelled with a barcode and registered with a scanner. All important data is stored on our server and archived for at least ten years. In the case of a mistake during the production process we are able to associate and correct it by means of the barcode and production journal.

It is our responsibility to protect our nature and to deal with it economical. We take into account starting form product design, manufacturing, and delivery the goal to save raw materials and energy. Through process monitoring measures, energy recovery facilities and an audited energy management system, we are actively contributing to preserving our healthy environment Alle wichtigen Daten werden auf einem Server gespeichert und zehn Jahre lang archiviert.